In the world of high-performance cookware, material quality is only part of the story. Equally critical is how those materials are combined. For triply stainless steel discs – the bases of many pots, pans and pressure cookers – the bonding process is key to ensuring superior cooking performance, durability and safety.

What Is a Tri-Ply Stainless Steel Disc?

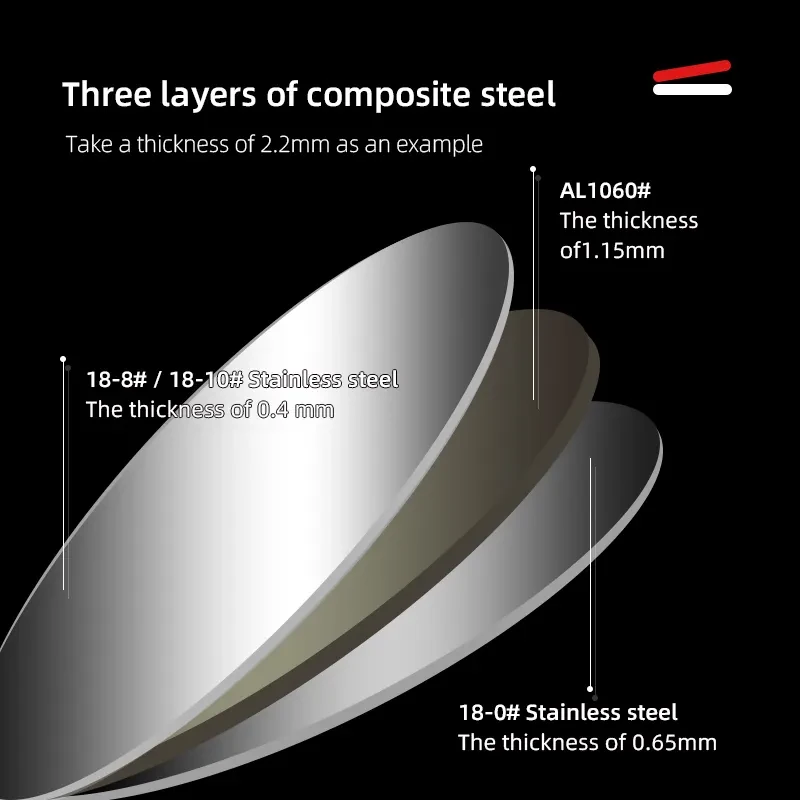

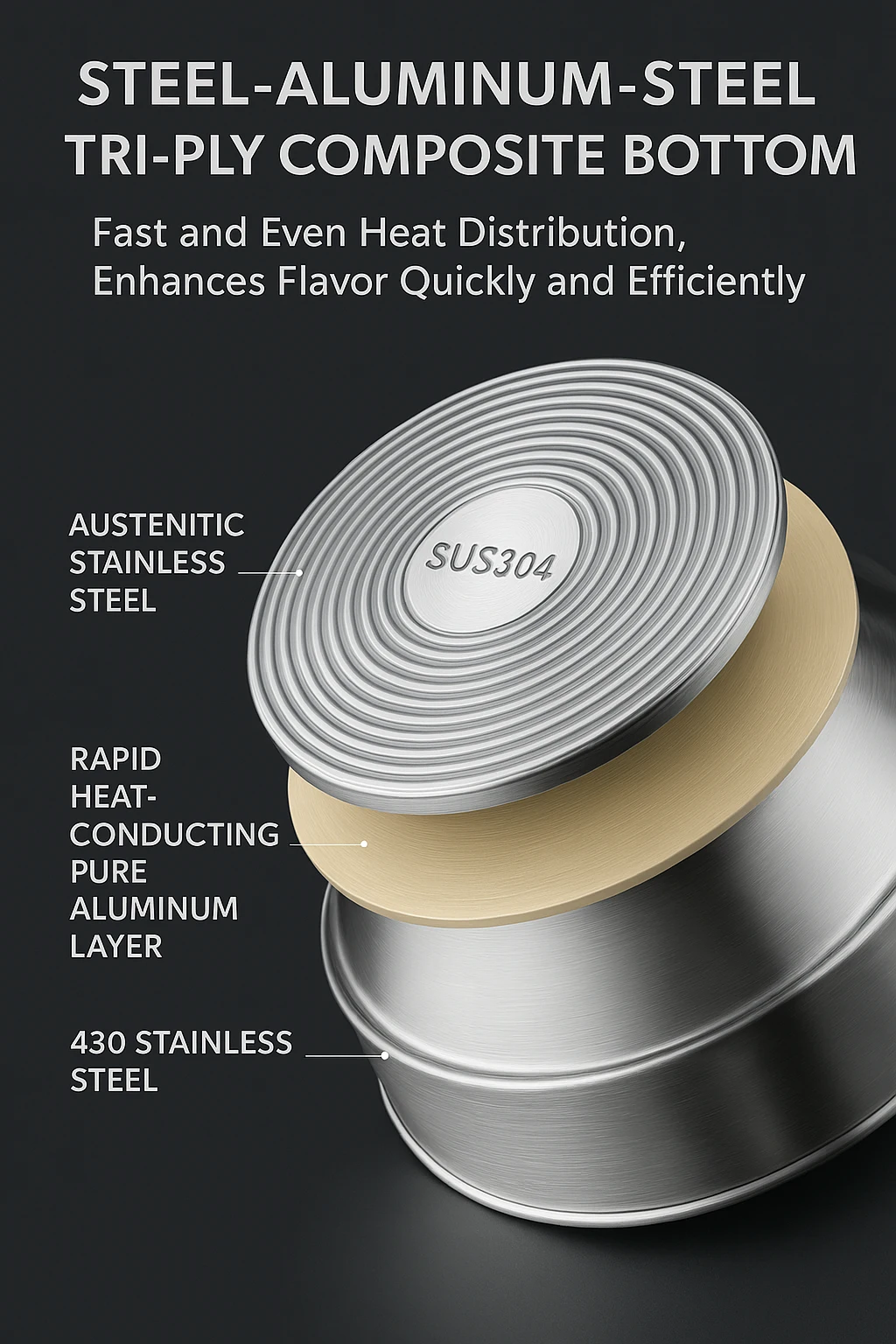

A tri-ply stainless steel disc typically consists of three layers:

- Stainless steel (outer layers) for corrosion resistance, strength, and food safety.

- Aluminum (core layer) for superior heat conductivity and even distribution.

These layers are fused together to form the base of cookware, providing the best of both worlds—durability and heat performance. But how effectively these layers function together depends entirely on the bonding technology used.

Why Bonding Technology Matters

Efficient Heat Transfer

Without proper bonding, gaps or air pockets can form between layers, disrupting heat flow. Advanced bonding techniques like impact bonding or cladding eliminate this problem, ensuring:

- Faster heat-up times

- Even heat distribution with no hotspots

- Energy efficiency

Durability & Structural Integrity

Bonding isn’t just about holding materials together—it’s about making them work as one. Poor bonding can lead to warping, separation, or delamination over time. High-quality bonding guarantees:

- Long-lasting cookware performance

- Resistance to high temperatures and heavy-duty use

- Stability during sudden temperature changes

Induction Compatibility

Induction cooktops require magnetic stainless steel at the base. A well-bonded tri-ply disc ensures the magnetic layer remains fully functional and securely attached, providing:

- Full compatibility with modern kitchens

- Maximum energy transfer on induction stovetops

Safety and Hygiene

Bonding also affects food safety. A poorly fused disc can trap food particles or moisture between layers, creating hygiene risks. Advanced bonding ensures:

- Smooth surfaces with no crevices

- Easy-to-clean and hygienic construction

- 100% food-safe performance

Common Bonding Techniques

- Impact Bonding: Uses high-pressure machines to mechanically bond layers, ideal for thick base discs.

- Cladding (Roll Bonding): Rolls metal sheets under high heat and pressure to create a uniform composite material—used for full-body tri-ply cookware.

- Friction Bonding: Uses heat from friction to bond discs, suitable for smaller or thinner cookware bases.

Final Thoughts

In today’s competitive cookware market, product performance and durability are critical, and bonding technology plays a decisive role in this. Prioritizing cutting-edge bonding processes is more than just a technical choice; it is a strategic advantage that improves product quality, customer satisfaction, and brand reputation.

About Hengguang

Hengguang is a trusted tri ply stainless steel material manufacturer with over 30 years of industry experience, with advanced production lines and strict quality control systems, using advanced impact bonding and roll-compounding technology to ensure seamless fusion of stainless steel and aluminum. These processes create a unified structure with excellent thermal conductivity, high strength, and long-lasting stability, which is ideal for induction cooker-compatible high-performance cookware.